Keeping the Material Clean & Free of Scale

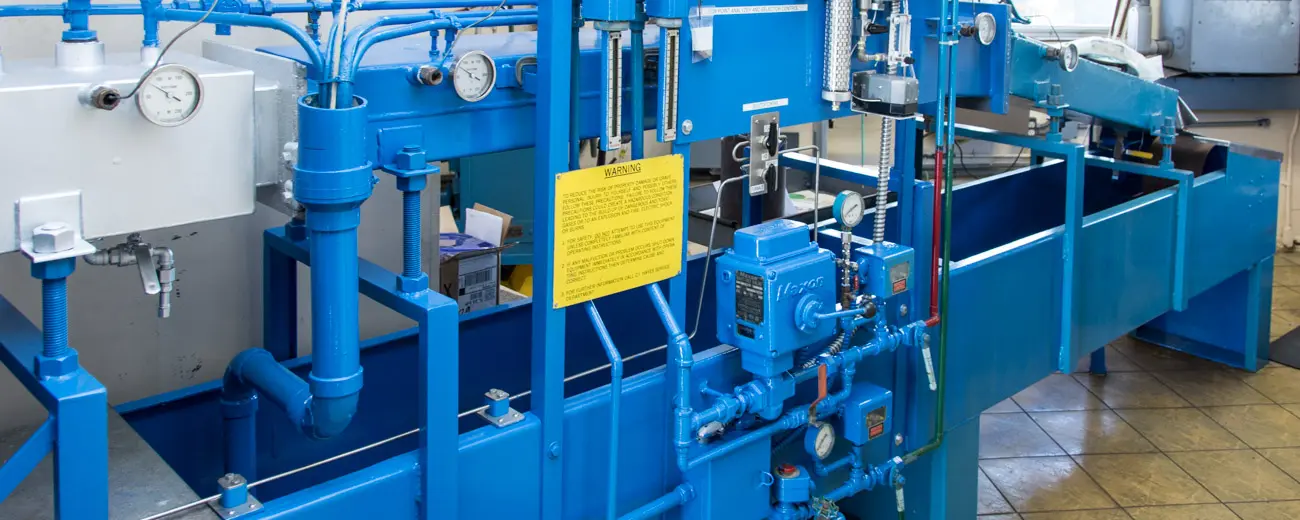

Atmospheric Brazing Utilizing Hydrogen

The brazing or heat treating is done in a continuous belt furnace with a Hydrogen atmosphere to keep the material clean (normally cleaner than as received) and free of scale. Hydrogen acts like a flux, so none is needed when brazing. This furnace can handle a large volume of smaller parts which makes it more economical for our customers. The furnace uses a variable speed drive for controlling the belt speed to ensure the material is at heat for a specific time. Also, the material travels through four cooling chambers to cool it to room temperature before exiting the furnace.

Hydrogen Brazing creates high integrity braze joint by utilizing a process that uses the cleaning (reducing) properties of high temperature and high purity hydrogen to drastically improve the wetting characteristics of your chosen braze alloy.

Employing the high-temperature hydrogen atmosphere offers reduced surface oxides which enable the braze alloy to wet more thoroughly.