Offering Various Types of Brazing Services in Jupiter, FL

Which Brazing is Right for Your Product?

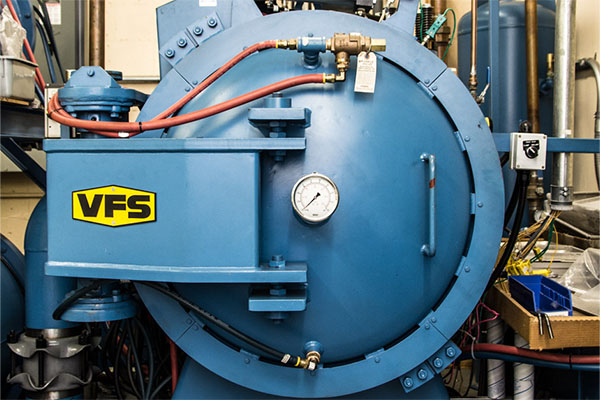

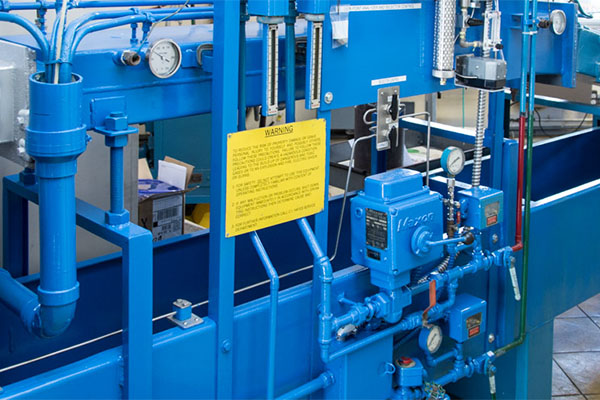

When joining machine parts, there are several ways of obtaining a strong permanent bond. TIG, MIG, or EB welding all have their place, but if localized heat distortion, cost, or oxides are a problem, you need hydrogen or vacuum furnace brazing for your product.

Hydrogen is reducing, and the vacuum is inert, so no flux is needed or wanted! There’s no cleanup. Second, in most cases, finished assemblies are brighter than the ones produced. Next because furnace brazing utilizes capillary action, so the entire joint area is completely sealed with a metallurgical bond.

You receive strong joints and clean, attractive assemblies at a reasonable price. A brazing alloy can be selected to coincide with the proper solution temperature of Austenitic Stainless Steels or the hardening temperature of a Martensitic Stainless Steels to obtain the final design properties in the base material.

But also, the capability for bright tempering of tool steels and stainless steels. Age hardening of Precipitation Hardening Stainless Steels can be kept bright during the process.

The Different Types of Brazing Styles

Why is Brazing Your Best Option?

Brazing does not melt the base metal of the joint; it allows much tighter control over tolerances and produces a clean joint without the need for secondary finishing.

Braze many items at once, from small batches to huge runs.

Multi-part and complex assemblies allow for the simultaneous joining of several parts at once.